| Catalog Number |

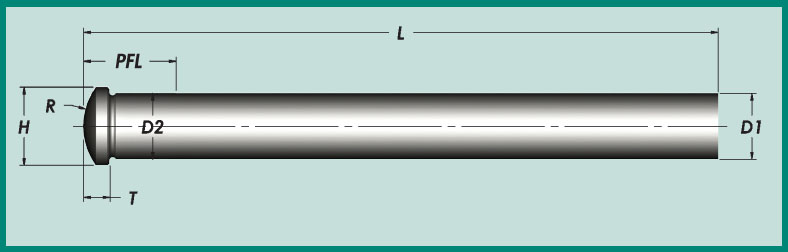

Diameter +.0000 -.0005 |

L +.50 -.00 |

H +.000 -.010 |

T +.000 -.005 |

D2 +.0000 -.0005 |

PFL +.00 -.06 |

R SPH RAD |

| RAP37L06 | .3740 | 6" | .500 | .250 | .3765 | 7/8 | .375 |

| RAP37L10 | .3740 | 10" | .500 | .250 | .3765 | 1-3/8 | .375 |

| RAP50L06 | .4990 | 6" | .625 | .250 | .5015 | 7/8 | .500 |

| RAP50L10 | .4990 | 10" | .625 | .250 | .5015 | 1-3/8 | .500 |

| RAP62L06 | .6240 | 6" | .750 | .250 | .6265 | 7/8 | .625 |

| RAP62L10 | .6240 | 10" | .750 | .250 | .6265 | 1-3/8 | .625 |

| RAP75L10 | .7490 | 10" | .875 | .312 | .7515 | 1-3/8 | .750 |

| RAP75L14 | .7490 | 14" | .875 | .312 | .7515 | 1-3/8 | .750 |

| RAP100L10 | .9990 | 10" | 1.125 | .312 | 1.0015 | 1-3/8 | 1.00 |

| RAP100L14 | .9990 | 14" | 1.125 | .312 | 1.0015 | 1-3/8 | 1.00 |

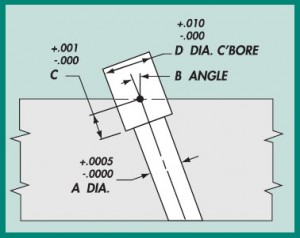

These pins are supplied with a spherical radius premachined on the head which eliminates angle grinding usually required on the head.

To install on a specific angle use the chart to determine counterbore depth.

Installation notes:

Cut angle pin to length as required to obtain required travel on the slide. The angle pin works on angle in clearance hole in slide to push the slide & create travel.

| Pin “A” Diameter |

Angle | C’bore Depth “C” |

C’bore Dia. “D” |

| .3765 | 10° | .256 | .562 |

| 15° | .264 | .562 | |

| 20° | .275 | .562 | |

| 25° | .291 | .562 | |

| .5015 | 10° | .258 | .688 |

| 15° | .268 | .688 | |

| 20° | .283 | .688 | |

| 25° | .304 | .688 | |

| .6265 | 10° | .260 | .812 |

| 15° | .273 | .812 | |

| 20° | .291 | .812 | |

| 25° | .316 | .812 | |

| .7515 | 10° | .324 | .938 |

| 15° | .339 | .938 | |

| 20° | .361 | .938 | |

| 25° | .389 | .938 | |

| 1.015 | 10° | .328 | 1.188 |

| 15° | .348 | 1.188 | |

| 20° | .377 | 1.188 | |

| 25° | .415 | 1.188 |

© EDM Sales & Supplies, Inc.- All Rights Reserved