24 Volt Electric Control & Touch Screen Control Panel

Lubrication System

A fully automatic hydrostatic system is employed on the sideways. An alarm alerts the operator when the oil gets low preventing damage to the machine.

Chiller for Hydraulic Oil

A separate hydraulic unit is equipped with a chiller system to avoid transference of heat and vibration from hydraulic system to the machine.

Spindle and Wheel Head

The extra rigid designed spindle is suitable for heavy duty grinding. The grinding spindle is supported by six pieces of super precision angular contact, preloaded bearings with permanent life time grease lubrications. The interchangeable spindle is mounted in the rigid wheelhead. It is driven by a dynamically balanced 15 HP motor via a flexible coupling to eliminate deflection and vibration. This permits an exceptional grinding quality finish.

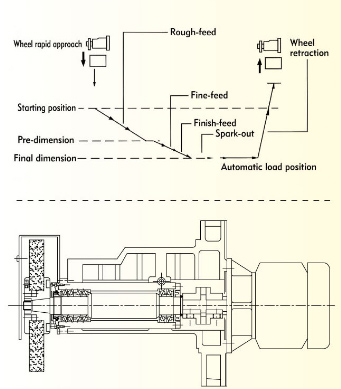

Automatic Grinding Cycle

Powerful TLC Touch Screen Control

Features and Construction

GT Column Surface Grinders 2A-2Axis Automatic, 3A-3Axis Automatic

| Model | PNC | GT 2448 | GT 2460 | GT 2480 | GT 24100 | GT 24120 | GT 3248 | GT 3260 | GT 3280 | GT 32100 | GT 32120 |

| Table Clamping Software (WXL) inch | W | 24 | 32 | ||||||||

| L | 53 | 65 | 84 | 104 | 124 | 53 | 65 | 85 | 104 | 124 | |

| Maximum Cross Travel | Inch | 26 | 33.86 | ||||||||

| Maximum Grinding Area (inch) | W | 24 | 31.89 | ||||||||

| L | 49 | 61 | 80 | 100 | 120 | 49 | 61 | 80 | 100 | 120 | |

| Max distance between spindle centre to table | MPG inch | 31.5 / 39.4 (optional) | 31.5 / 39.4 (optional) | ||||||||

| Down feed per division | MPG inch | 0.0001, 0.0005, 0.001 | 0.0001, 0.0005, 0.001 | ||||||||

| Down feed per revolution | MPG inch | 0.01,0.05,0.1 | 0.01,0.05,0.1 | ||||||||

| Auto down feed servo motor | inch | 0.0005-0.002 | 0.0005-0.002 | ||||||||

| Longitudinal Table Speed | fpm | 10-105 | 10-105 | ||||||||

| Crossfeed intermittent | Inch / feed | 0.004-1.57 | 0.004-1.57 | ||||||||

| Crossfeed continuous | fpm | 0-9.5 | 0-9.5 | ||||||||

| Crossfeed per division | inch | 0.0001, 0.001, 0.005 | 0.0001, 0.001, 0.005 | ||||||||

| Grinding Wheel Dimensions (ODXIDXWidth) | 20X5X2 (20X5X3 optional) | 20X5X2 (20X5X3 optional) | |||||||||

| Spindle Speed (50/60HZ) (R.P.M) | 1450/1720 | 1450/1720 | |||||||||

| Spindle Motor | HP | 15/25 (optional) | 15/25 (optional) | ||||||||

| Hydraulic pump motor 6 pole | HP | 7.5 | 7.5 | 7.5 | 7.5 | 10 | 7.5 | 7.5 | 7.5 | 7.5 | 10 |

| Total Power Motor | HP | 24/34 | 24/34 | 24/34 | 24/34 | 26.5/36.5 | 24/34 | 24/34 | 24/34 | 24/34 | 26.5/36.5 |

| Floor Space (HXWXL) (inch) | L | 187 | 211 | 250 | 289 | 329 | 187 | 211 | 250 | 28- | 329 |

| W | 117 | 135 | |||||||||

| H | 96.8 | 102.7 | |||||||||

| Net Weight Approx | lbs | 14300 | 16060 | 18920 | 22000 | 24200 | 17380 | 19140 | 22220 | 25300 | 27940 |

| Chuck Weight | lbs | 700 | 800 | 1190 | 1490 | 1790 | 1200 | 1310 | 2070 | 2590 | 3100 |

| Maximum workpiece on chuck | lbs | 2640 | 3300 | 3960 | 3960 | 4400 | 2640 | 3300 | 3960 | 3960 | 4400 |

Standard Accessories

Optional Accessories

© EDM Sales & Supplies, Inc.- All Rights Reserved